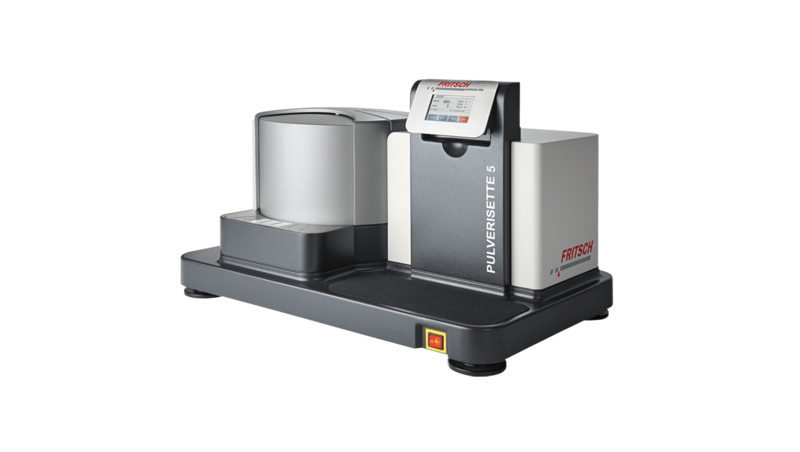

| Cihaz Türü | Gezegen (Planetary) Bilyalı Değirmen |

| Kullanım Amacı | Yüksek Enerjili Öğütme, Karıştırma ve Homojenleştirme |

| Uygulama Modu | Kuru Öğütme ve Islak Öğütme |

| Uygun Numune Tipleri | Sert, Orta Sert, Kırılgan ve Lifli Malzemeler |

| Maks. Besleme Tane Boyutu | 10 mm |

| Ulaşılabilen Son İncelik | < 1 ?m |

| İstasyon Sayısı | 2 veya 4 |

| Toplam Numune Kapasitesi | 450?900 ml |

| Öğütme Kabı Hacimleri | 15?500 ml |

| Ana Disk Hızı | 50?800 rpm |

| Öğütme Kabı Maks. Hızı | 1600 rpm'ye kadar |

| Maks. Santrifüj İvmesi | 22?64 g |

| Atmosfer Seçenekleri | İnert Gaz Altında Öğütme |

| İzleme Seçenekleri | Basınç ve Sıcaklık Takibi |

| Güvenlik Özellikleri | Kap Kilitleme Sistemi, Dengesizlikte Otomatik Durdurma |

| Operasyonel Kolaylık | Çalışma Parametrelerinin İzlenmesi |

| Kap ve Bilya Malzemeleri | Akik, Zirkonya, Paslanmaz Çelik, Tungsten Karbür |

| Bilya Çap Aralığı | 0.1?20 mm |

Metalurji, Seramik, Jeoloji/Mineraloji, Toz Metalurjisi, Kompozit ve Genel Numune Hazırlama

Sümran Bilgin, Bülent Öztürk, Furkan Alptekin, Sefa Emre Sünbül, Sultan Öztürk, Kürşat İçin

2025In this study, the phase structure formed during the mechanical alloying preparation of Ni-doped Co4Fe2Nix(Al1.5Mn1.5)3 (x = 0, 0.5, and 1.0) high-entropy alloys (HEAs) prepared via the mechanical alloying method was examined to investigate the relationship between the changes in phase structure and magnetic properties through hysteresis curves and FORC analysis. As a result of the mechanical alloying process, intense agglomeration of particles was observed, and the particle size was determined to vary between 2.36 and 5.57 ?m. Contrary to the theoretically calculated phase structure, it was found that not only the BCC phase but also the FCC and Laves phases were formed in the structure after mechanical alloying. Contrary to these analyses, microstructural examinations revealed that the BCC phase, which has a regular structure, transformed into the D03 phase due to the rapid solidification effect. Additionally, regions rich in Al, Mn, and Co were identified in the microstructure. Magnetic measurements resulted in saturation magnetization (Ms) values of 113.0, 111.6, and 112.7 emu/g for Ni0, Ni0.5, and Ni1.0 samples, respectively; intrinsic coercivity (Hci) values were determined as 171.3, 168.9, and 171.4 Oe. FORC analysis indicated that Ni addition narrows vertical diffusion and partially facilitates domain wall movement; however, structural irregularities in some samples contributed to increased intrinsic coercivity and the presence of non-ferromagnetic phases.

Mertcan Kafali, Kadir Mert Doleker, Azmi Erdogan, Sefa Emre Sunbul, Kursat Icin, Ataberk Yildiz, Mustafa Sabri

2023High entropy alloys have promising wear, oxidation, and corrosion properties compared to conventional alloys and superalloys. In the present study, CrCuFeNiAl0.5 and CrCuFeNiAl0.5Si0.5 alloys were prepared using a traditional powder metallurgy process and then remelted the surfaces via laser. The laser remelting (LR) process gains a denser and more homogeneous surface to alloys. Pressureless consolidated and laser-remelted specimens were subjected to wear, corrosion, and oxidation tests. In the wear tests, it was observed that the wear resistance of Si-containing samples was better due to higher hardness. However, the laser remelting process has mostly increased rather than reduced wear losses. The less volume loss of laser-melted samples was attributed to the almost pure Cu in its content. There is little difference among all samples in electrochemical corrosion measurements. The formation of a fragile passivation layer was observed in potentiodynamic polarization curves of CrCuFeNiAl0.5Si0.5 and LR-CrCuFeNiAl0.5Si0.5 alloys. The alloy with the best corrosion resistance is CrCuFeNiAl0.5Si0.5, whose icorr value is 0.936 × 10-6 A/cm2. After high-temperature oxidation tests, the CrCuFeNiAl0.5 alloy exhibited the worst oxidation performance due to not forming a protective oxide layer on the surface, while LR enabled the protective oxide scale in a short oxidation time. The presence of Si in this alloy relatively enhances the oxidation resistance. The best oxidation performance was observed in LR-CrCuFeNiAl0.5Si0.5 due to the forming of a protective Al2O3 layer during the oxidation tests.

Zafer Gölbaşı, Bülent Öztürk, Sefa Emre Sünbül, Kürşat İçin

2023In this study, Ti?6Al?xNb alloys with different Nb percentages (x = 3.5?21 wt%) were produced by the conventional powder metallurgy technique. After mixing and pressing the alloy powders in appropriate proportions, the green samples were sintered in a tube furnace under a vacuum atmosphere at 1200 °C for 2 h. The X-ray diffraction analysis (XRD) showed that all the alloys consist of ?-Ti, TiNb (?-Ti) and AlNb2 phases. The results showed that the Ti?6Al?14Nb alloy among all alloys has the best mechanical properties, and the microhardness, tensile and flexural strength are 276.4 Vickers hardness (Hv0.2), 453 MPa and 1682 MPa, respectively. Tribological tests were carried out in both dry and wet conditions with Hanks' Balanced Salt Solution. While generally, the specific wear rates of the samples increased with Nb content up to 17.5 wt% under dry conditions, on the other hand, they increased with increasing Nb content under wet conditions. On the other hand, the specific wear rate increased with increasing the sliding distance. The best corrosion resistance alloy among all the samples was Ti?6Al?7Nb with -0.0968 V corrosion potential (Ecorr), 0.015 ?A/cm2 corrosion current density (Icorr) values.

Kürşat İçin, Selmine Akyol, Furkan Alptekin, Ataberk Yıldız, Sefa Emre Sünbül, İbrahim Ergin, Sultan Öztürk

2023The aim of this study is to enhance the magnetic and thermal properties of strontium hexaferrites by substituted with Al, Cr, and Mn ions instead of Fe, and to elucidate the changes in their structural, morphological, and thermal characteristics, in detail. SrFe12-xMxO19 (M: Al, Cr, Mn; x = 0.1, 0.3, and 0.5) powders were produced by the mechanochemical synthesis method from mill scale, which is a solid waste in steel production. While the Al3+ substitution did not cause any change in the phase structure, the Cr3+ and Mn3+ caused the formation of nanosized ?-Fe2O3 and MnxFe2-xO4 phases in the structure, respectively. Increasing the Al substitution ratio led to a decrease in crystal size, from 176 nm to 32 nm. Similarly, the substitution of Cr resulted in a decrease in crystal size to 78 nm. However, Mn substitution had the opposite effect, increasing the crystal size of the powders. Al3+, Cr3+, and Mn3+ substitutions led to various effects on magnetic properties due to their placement in different lattice sites in the SrFe12O19 hexagonal crystal. The residual or remanent magnetization (Mr) and saturation magnetization (Ms) were lower than the initial values of Mr = 41.76 and Ms = 69.94 emu/g depending on the type and ratio of substitution ions. The highest coercivity was observed as 7116 Oe for SrFe11.5Al0.5O19. The Curie temperature increased to 515 °C with Cr3+ substitution but decreased to 431 °C and 426 °C with Al3+ and Mn3+, respectively.

Sümran Bilgin, Sultan Öztürk, Kürşat İçin

2023In this our current research, the effect of Sr/Fe on the phase formation and magnetic properties of strontium hexaferrite powders synthesized by mechanochemical synthesis and heat-treated at 950 °C for 1 hour under an open atmosphere was investigated. XRD patterns revealed that the primary phase in all powders was identified as the SrFe12O19 phase. The SEM image showed that the particles had a round morphology with partial agglomeration due to the reduction in particle size. The magnetic properties were found to be affected by Sr/Fe ratio. The (BH)max values increased from 0.35 MGOe to 3.11 MGOe as the Sr/Fe increased from 1:11.0 to 1:12.0. The presence of secondary phases such as ?-Fe2O3 and SrO weakened the magnetic properties. The weight fraction of the SrO phase increased with a decrease in stoichiometry from 1:12 to 1:11, which correlated with the weakening of the magnetic properties. The study concludes that the Sr/Fe ratio between Sr/Fe is a critical parameter in determining the magnetic properties of strontium hexaferrite powders.

Kürşat İçin, Sultan Öztürk, Damla Dilara Çakıl, Sefa Emre Sünbül, İbrahim Ergin, Bekir Özçelik

2022Today, waste management and recycling have critical importance given the dwindling natural resources and to create powerful technologies for a green future. One of these strontium hexaferrite powders were produced by mechanochemical process using mill-scale and strontium carbonate from obtained celestite ore. The strontium carbonate and the mill scale were prepared in stoichiometric ratio, and mechanochemical process was applied for 16 h to produce hard-ferrite powders. Following the mechanochemical synthesis process, powder mixture was annealed at 850?1000 °C temperatures. The morphology, crystal structure and phase composition of strontium hexaferrite powders caused the magnetic properties to change according to the annealing temperature. As a result of the studies, the most suitable annealing temperature was determined as 975 °C. The Hc, Br and (BH)max of produced powders correspond to 5505 Oe, 347 mT and 5.77 MGOe at 975 °C, respectively. The Curie temperature of the annealed powders was determined as 474 °C.

Yunus Emre Şimşek, Kadir Mert Döleker, Mehmet Kuru, Sefa Emre Sünbül, Kürşat İçin

2022Yüksek entropili alaşımlar sahip oldukları üstün özellikleri sayesinde süper alaşımlara alternatif olarak önerilmektedir. Yüksek entropili alaşımlar araştırılmaya devam ettikçe ortaya çıkan özgün ve üstün özellikleri sayesinde geniş alanlarda kullanılabilir olmasıyla birlikte önemi gittikçe artmaktadır. Bu çalışmada mekanik alaşımlama tekniği ile AlCuCrFeNi tozları sentezlenmiştir. Sentezlenen tozlarda YMK (Yüzey Merkezli Kübik), HMK (Hacim Merkezli Kübik) ve B2 fazları tespit edilmiştir. Tozlar peletlendikten sonra fiziksel buhar biriktirme (FBB) tekniği ile Monel 400 altlık malzeme üzerine biriktirilmiştir. Üretilen kaplamanın mikroyapısal özellikleri incelenmiştir. Üretim sonrası homojene yakın bir ince film tabakası üretilmiştir.

Kürşat İçin, Sultan Öztürk, Damla Dilara Çakıl, Sefa Emre Sünbül

2021In the present study, the strontium hexaferrite (SrFe12O19) has been successfully produced from recycled mill scale and strontium carbonate (SrCO3) powders with stoichiometric ratio (SrCO3/Fe2O3) of 1:6 by mechanochemical synthesis process, followed by annealing at 975 °C temperature. As the mechanochemical synthesis time increased, the phase ratio of hard magnetically SrFe12O19 in the structure increased after the annealing, according to the XRD analysis. The SrFe12O19 phase formation temperature decreased from 851 °C to 762 °C with increasing mechanochemical synthesis time. Also, FTIR analysis showed that The C?O bond peaks are only visible for a 2 h synthesis time at 854 cm-1 wavenumbers. Magnetic properties have changed according to particle size, activation energy, and phase ratios. The best magnetic properties were obtained with the application of 16 h of synthesis time. The coercivity values of 3.3, 3.6, 4.6, 5.5, 5.4, and 3.7 kOe were obtained for 2, 4, 8, 16, 32, and 64 h of mechanochemical synthesis times, respectively. The residual magnetization density (Br) values under 1 T magnetic field for the same synthesis times were obtained as 168, 221, 292, 347, 314, 258 mT, respectively.

Azmi Erdoğan, Sefa Emre Sünbül, Kürşat İçin, Kadir Mert Döleker

2021AlCrFeNiX (X = Cu, Si, Co) high entropy alloys (HEAs) were produced by mechanical alloying and sintering. The effects of the "X" additive on the microstructure, hardness, wear, and high-temperature oxidation behavior of HEAs were investigated. Different phases occurred in AlCrFeNiX HEAs depending on the "X" element. In addition to the BCC phase in all alloys, there are FCC phases in AlCrFeNiCu and AlCrFeNiCo alloys and two different intermetallic phases AlCrFeNiSi alloy. High negative mixing enthalpy values were found to be effective in phase and microstructure formation. In the alloy containing Si, 750 HV micro-hardness was seen as the highest hardness value. In the alloys containing Co and Cu, 450 and 420 HV micro-hardness values were determined, respectively. The best wear resistance and the lowest friction coefficient were seen in the AlCrFeNiSi alloy. In the wear tests performed at different loads, the increasing load increased the wear losses. The isothermal oxidation tests were conducted to HEAs at 1000 °C for 5, 25, and 75 h. Each HEAs exhibit very well oxidation resistance under the current conditions due to the selective alumina formation on the surface. It was not detected a dramatic difference in terms of oxidation behaviors of HEAs.

Üretim ücretlendirmesi için lütfen iletişime geçiniz.

Mekanik Alaşımlama, metal ve/veya seramik tozlarının yüksek enerjili bilyalı değirmenlerde (planetary değirmen gibi) belirli bir süre birlikte öğütülerek çok ince ölçekte karıştırılması ve alaşım/kompozit toz haline getirilmesi yöntemidir. Klasik ergitme ile alaşım üretmek yerine, tamamen katı halde ve toz fazında ilerleyen bir süreçtir.

İşlem sırasında öğütme kabı içindeki bilyalar, tozlara sürekli darbe ve kesme kuvveti uygular. Bu etkiyle toz parçacıkları:

kırılır (parçalanır),

ezilir (incelir),

birbiri üzerine yapışıp kaynaklanır (soğuk kaynak),

tekrar kırılıp yeniden karışır.

Bu kırılma + soğuk kaynak + yeniden kırılma döngüsü tekrarlandıkça, bileşenler mikroyapı düzeyinde birbirine daha iyi karışır ve homojenleşir. Sonuç olarak çok ince taneli, homojen dağılımlı ve istenen bileşimde tozlar elde edilir.

Mekanik alaşımlama ile genellikle:

Birbirinde zor çözünen veya normal yöntemlerle karıştırılması zor olan malzemeler bir araya getirilebilir.

Nanoyapılı veya ultra ince taneli tozlar üretilebilir.

Seramik takviyeli metal matris kompozit tozları hazırlanabilir.

Presleme ve sinterleme gibi sonraki üretim adımları için daha homojen başlangıç tozu sağlanır.

Kısacası mekanik alaşımlama, tozları yüksek enerjili öğütme ile çok ince ölçekte karıştırarak yeni alaşım ve kompozit tozlar üretmeye yarayan pratik bir katı-hal yöntemidir.

04 Şubat 2026